SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

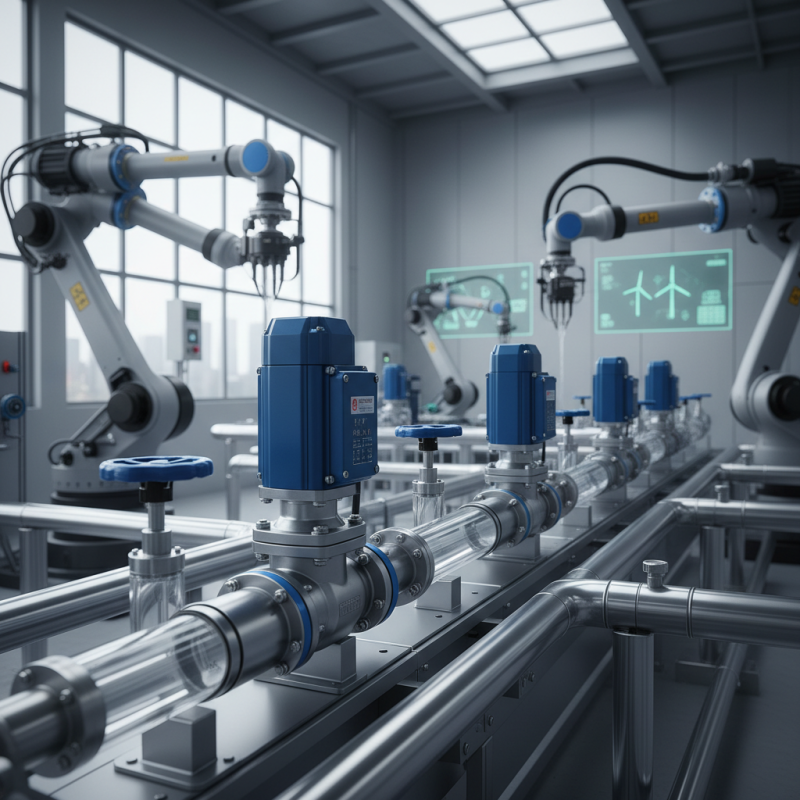

In modern industrial applications, Electric Ball Valves are gaining popularity. These valves offer unique advantages that are hard to overlook. They provide precision control over fluid flow, which is essential for many projects.

The integration of Electric Ball Valves enhances operational efficiency and reduces manual intervention. This automation leads to a safer working environment and minimizes potential errors. However, their installation and maintenance require careful planning. Understanding these challenges is key to maximizing their benefits.

Electric Ball Valves can sometimes be overlooked due to cost concerns. Yet, their longevity and reliability often outweigh these initial expenses. Ensuring correct usage and setup can result in significant savings and better performance. Embracing these valves might reshape how projects function in the long run. But, ongoing evaluation is necessary to fully grasp their impact.

Electric ball valves offer several advantages over traditional valves. They provide precise control over fluid flow, which is crucial for many applications. The speed of operation is a notable benefit. Electric valves can open or close quickly. This feature is vital in processes requiring immediate response.

Maintenance is another important aspect. Electric ball valves have fewer moving parts compared to mechanical options. This simplicity often leads to lower maintenance costs and reduced downtime. However, the initial installation might require more expertise. It’s essential to ensure proper wiring and control systems are in place.

Reliability is a significant concern in any project. Electric ball valves operate consistently, minimizing the risk of failure. They also allow for remote operation, enhancing convenience. Yet, users might need to consider the implications of power outages. It’s crucial to have backup systems to ensure continued operation during disruptions.

Electric ball valves are revolutionizing industrial automation and control. They provide precise management of fluid flow in various systems. Automation World reported that implementing electric valves can improve efficiency by up to 30%. This increase results in significant savings and faster operations. Such efficiency is crucial in industries where precision impacts safety and performance.

One notable aspect of electric ball valves is their adaptability. They can be easily integrated into existing systems. This feature makes upgrades less complicated. However, the initial installation can be challenging. Sizing and compatibility require careful consideration. According to a study by the International Society of Automation, 25% of automation failures stem from improper valve selection. It’s essential to address these challenges proactively.

Furthermore, electric ball valves enhance real-time data collection. This capability allows for better monitoring and control. Reports indicate that real-time feedback can reduce downtime by 20%. Yet, many facilities still rely on outdated methods. Transitioning to electric solutions demands investment in training and technology. Embracing these innovations creates new challenges but can yield substantial long-term benefits.

Electric ball valves are increasingly becoming essential in modern projects. One significant advantage lies in their energy efficiency. According to a 2021 report by the American Society of Mechanical Engineers, facilities can save up to 30% on energy costs by using electric ball valves compared to traditional options. This reduction results from precise control over fluid flow, minimizing waste and enhancing overall system performance.

Operational costs are also lower with electric ball valves. A study by the International Energy Agency indicates that automation in valve systems can cut maintenance costs by up to 25%. Fewer mechanical parts mean fewer failures and repairs. Over time, this leads to significant savings for businesses.

Tip: Regularly monitor your electric ball valves for signs of wear. Early intervention can prevent costly downtime.

Another interesting point is the ease of integration with smart systems. Electric ball valves are designed to work with these technologies, increasing efficiency further. However, installation can be tricky for those unfamiliar with electrical systems. Ensure your team is equipped with the right tools and training.

Tip: Consider investing in training for your staff to maximize the benefits of these advanced systems. Better knowledge leads to better performance.

Electric ball valves are becoming popular in various projects due to their enhanced durability. One of the key advantages is their longer lifespan. Unlike traditional valves, electric ball valves use advanced materials that resist corrosion. This feature ensures that they remain functional for extended periods under harsh conditions. Their ability to withstand extreme temperatures is another asset.

Maintenance requirements for electric ball valves are significantly lower. These valves are designed with fewer mechanical parts, reducing the likelihood of wear and tear. Their simple construction means less time spent on repairs. Users can install them with minimal assistance. This ease of use leads to fewer errors during installation. However, it’s important to keep a maintenance schedule in mind. Neglecting this can still lead to issues down the line.

While electric ball valves are reliable, they are not foolproof. Regular checks are still necessary to ensure they function correctly. Occasionally, they may require recalibration or software updates. Some may find these updates inconvenient. Yet, the long-term savings on maintenance often outweigh these minor hassles. Careful planning can mitigate potential risks, ensuring a seamless operation for projects.

Electric ball valves offer remarkable versatility and adaptability, making them ideal for various projects. These valves can control the flow of liquids and gases in different applications. In industrial settings, they provide quick response times and efficient operation. Reports indicate that the use of electric ball valves can lead to a 30% reduction in energy usage compared to traditional options. This efficiency contributes to lower operational costs in the long run.

When considering project needs, think about the specific requirements. Electric ball valves can be customized to fit various sizes and pressure ratings, which is a significant advantage. They are suitable for both residential and commercial applications. Their ability to integrate with automation systems enhances flexibility in managing complex processes. Yet, it’s essential to ensure that installations comply with local regulations. Inadequate installation can lead to failures or inefficiencies.

Tips: Always evaluate the materials used in the valve components. Some may not be compatible with certain fluids, leading to unexpected issues. Regular maintenance checks are also vital, as wear and tear can affect performance. Lastly, consider the control system in use. A mismatch might limit the valve's capabilities in your project. Proper planning pays off significantly.