SUNDI TOOLS

- Copyright © Wuxi Sundi Precision Tools Co.,LTD All rights reserved.

- Site Map

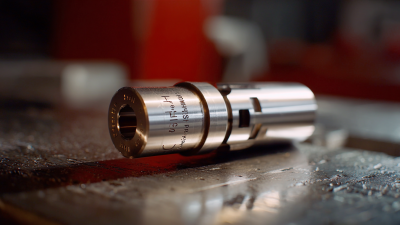

Choosing the right tool for your project is essential for achieving optimal results, especially when it comes to precision engineering tasks. Among the various tooling options available, the Step Reamer stands out due to its ability to create stepped holes that cater to specific dimensional requirements. According to a report by the American Tool Manufacturers Association, the global demand for reaming tools, including Step Reamers, is projected to grow at a CAGR of 4.5% by 2025, driven by advancements in automated manufacturing processes and an increase in aerospace and automotive applications.

Understanding the nuances of different Step Reamer designs, such as size, material, and application suitability, is crucial for selecting the right tool to ensure efficiency and accuracy in your project. This guide will equip you with the knowledge needed to make an informed decision when choosing the perfect Step Reamer for your needs.

When selecting the right step reamer for your project, it is essential to understand the various types available on the market. Step reamers are versatile tools designed to enlarge and shape holes in materials such as metal, wood, and plastic. The most common types include straight and spiral fluted reamers. Straight fluted reamers excel at cutting in a straight line, making them ideal for precision work, while spiral fluted reamers are better suited for removing chips and debris, which is crucial in applications where material build-up can hinder performance.

According to the 2022 Tooling Industry Report, over 40% of professionals in machining prioritize tool efficiency and versatility when selecting reamers. Choosing the right type can significantly impact productivity, accuracy, and overall project outcomes.

Tips: When deciding on a step reamer, consider the material you will be working with and the desired hole dimensions. Ensure the reamer's size matches your drill and is compatible with your material type. Additionally, always review manufacturer specifications to verify the tool's durability and performance ratings, which can save time and costs in the long run.

When selecting the appropriate step reamer for your project, it is crucial to assess specific project requirements, including material type, size, and tolerance specifications. According to a recent industry report by the Tooling & Manufacturing Association, selecting the correct reamer can improve hole quality by up to 30% while reducing tool wear. Different materials demand distinct reamer designs; for example, high-speed steel reamers are best suited for softer metals like aluminum, while cobalt or carbide options excel in machining harder materials like stainless steel.

Furthermore, size and tolerance are critical factors in ensuring optimal performance. A precise fit is necessary, as an inadequate tolerance can lead to excessive wear on both the tool and the workpiece. The American National Standards Institute (ANSI) recommends ensuring that the reamer's diameter matches the intended hole size, allowing for a tolerance range of no more than ±0.002 inches for precision applications. With these considerations in mind, projects involving tight tolerances or hard materials will benefit from careful selection, ultimately driving both efficiency and accuracy in the machining process.

When selecting a step reamer for your project, understanding its key features is vital.

Coating plays a significant role in performance and longevity. For instance, carbide coatings can enhance wear resistance and extend tool life by up to 30%, reducing the frequency of tool changes and overall project downtime. Additionally, specialized coatings such as TiN (Titanium Nitride) not only provide improved hardness but also assist in reducing friction, thereby enhancing the cutting efficiency during operation.

The design of the step reamer is another crucial aspect to consider. A well-engineered design can lead to smoother cuts and reduced vibration, which is essential for precision work. According to a recent industry report, reamers with tapered designs can provide a better finish on the workpiece and improve accuracy by up to 15% compared to standard designs. Also, pay attention to the reamer's flutes; deeper flutes allow for better chip removal, which is essential when working with materials like stainless steel, where chip buildup can lead to breaking.

Tips: Always verify the reamer's compatibility with the material you are working on. Consider using lubes or cutting fluids to further reduce friction and enhance the tool's lifespan. Finally, regularly inspect the reamer for wear to ensure optimal performance throughout your project.

When selecting a step reamer for your project, the manufacturer plays a crucial role in ensuring you receive a high-quality tool. Research shows that reputable manufacturers often dedicate resources to quality control and customer feedback, resulting in a more reliable product. According to a recent industry report, companies with high customer satisfaction ratings can produce tools that last up to up to 25% longer, showcasing the importance of choosing the right brand.

Tips: Always verify a manufacturer’s reputation by looking for certifications or industry awards. Online reviews can also provide insights into the performance and durability of their products. Checking forums or discussion groups can further guide your decision based on real user experiences.

In addition to reputation, consider the level of support services offered by manufacturers. Many top-tier brands provide comprehensive customer assistance, including detailed product guides, usage tutorials, and responsive customer service. A manufacturer with robust support services tends to foster a strong relationship with users, which can greatly enhance your experience. Remember, investing time in selecting a reputable manufacturer not only enhances project outcomes but also improves your overall satisfaction with the tool.

When selecting a step reamer for your project, it’s essential to balance cost and quality to stay within your budget while ensuring excellent performance. While lower-cost options may initially seem attractive, they often compromise durability and effectiveness. Quality tools are likely to deliver more precise results and withstand greater wear, reducing the risk of needing replacements. Therefore, investing in reputable brands can lead to long-term savings by minimizing repair and replacement costs.

To make an informed decision, consider employing project management tools that allow you to assess both budget constraints and the quality of the tools available. Features such as cost-benefit analysis can aid in determining the long-term value of higher-quality reamers versus cheaper alternatives. By integrating these financial assessments with your overall project management strategy, you can ensure that your choice not only fits within your budget but also contributes positively to the project's success.

| Type | Material | Size Range (inches) | Average Cost ($) | Quality Rating (1-5) |

|---|---|---|---|---|

| Standard Step Reamer | High-Speed Steel | 1/4 - 1 | 25 | 4 |

| Heavy-Duty Step Reamer | Cobalt Steel | 3/8 - 2 | 45 | 5 |

| Bimetal Step Reamer | Cobalt & HSS | 1/8 - 1-1/4 | 35 | 4 |

| Precision Step Reamer | Solid Carbide | 1 - 1-1/2 | 100 | 5 |

| Economy Step Reamer | High-Speed Steel | 1/4 - 1 | 15 | 3 |